Introduction

In today’s world of sustainable construction and efficient industrial processes, polyurethane foam insulation has emerged as one of the most versatile and effective materials available. From enhancing energy efficiency to providing structural support, this innovative material is used across a wide range of applications, ensuring durability, safety, and comfort. Among its various forms, rigid polyurethane foam stands out as a reliable solution for both commercial and residential projects. This article explores the properties, benefits, and applications of polyurethane foam insulation, drawing on insights from industry experts and real-world usage.

Understanding Rigid Polyurethane Foam

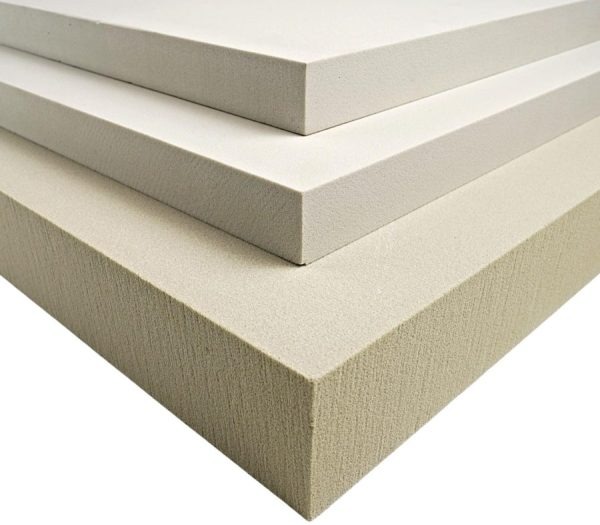

Rigid polyurethane foam (PUR) is a lightweight, high-performance material widely used in insulation and structural applications. Unlike flexible foams, rigid foams maintain their shape under pressure, offering a strong, durable solution for multiple industries. Polyurethane foams, including polyisocyanurate (PIR) variants, are known for their excellent thermal conductivity, chemical resistance, and mechanical strength.

Originally developed in the mid-20th century, rigid polyurethane foams have grown to become essential in industries such as construction, automotive, refrigeration, and even furniture manufacturing. Their versatility allows them to bond with most materials, making them ideal for composite panels, cold storage rooms, and isothermal truck bodies.

Key Features of Polyurethane Foam Insulation

Polyurethane foam insulation provides a range of benefits that make it the material of choice for modern construction and industrial projects:

- Thermal Efficiency: With thermal conductivity values ranging from 0.022 to 0.028 W/m·K, rigid polyurethane foam offers excellent insulation. Closed-cell phenolic variants provide even lower thermal conductivity (0.018 W/m·K), helping reduce energy consumption and long-term costs.

- Structural Strength: These foams exhibit a high strength-to-weight ratio, making them suitable for structural applications like pipe supports, composite panels, and walk-on ceilings. High-density foams can support static weights of up to 225 tonnes per square meter.

- Chemical Resistance: Polyurethane foams resist solvents, oils, polyester resins, and styrene, ensuring longevity even in demanding industrial environments.

- Moisture Resistance: Non-wicking and highly resistant to water vapor, these foams prevent moisture buildup and mildew growth, protecting the integrity of insulation systems.

- Fire Performance: Phenolic foams, in particular, are thermoset materials that resist combustion, emit minimal smoke, and can achieve multiple European fire certifications. Class 0 foams are treated for nil burn rates, ideal for engine rooms, generator canopies, and other high-heat environments.

Applications of Rigid Polyurethane Foam

The range of applications for rigid polyurethane foam and polyurethane foam insulation is extensive, covering commercial, industrial, and residential sectors.

1. Construction and Building Insulation

In the construction sector, polyurethane foams are invaluable. CE-marked insulation panels are available in densities from 33 to 60 kg/m³, providing excellent thermal performance for walls, roofs, and floors. Phenolic foams, with closed-cell structures, offer superior thermal resistance while being lightweight and durable.

Additionally, polyurethane foam insulation contributes to energy efficiency, reducing heating and cooling costs and supporting environmental sustainability initiatives. Its high fire resistance ensures that buildings meet stringent safety standards, making it suitable for high-rise projects.

2. Refrigeration and Cold Storage

Rigid polyurethane foam’s low thermal insulation coefficients make it ideal for refrigeration applications. It is widely used in composite panels for cold storage rooms, refrigerated transport vehicles, and isothermal truck bodies. The combination of thermal efficiency and structural integrity ensures that temperature-sensitive goods remain safe during transport and storage.

3. Automotive and Transportation

Polyurethane foams are used extensively in the automotive industry for insulation, soundproofing, and structural components. Acoustic barrier products made from polyurethane membranes reduce noise transmission and vibration in vehicles, while rigid foams provide lightweight structural support for buses, coaches, and rail applications.

4. Marine and Aerospace

From boat-building to aircraft interiors, rigid polyurethane foam are trusted for their strength, low weight, and fire-resistant properties. They are commonly used as core materials in composite panels, enhancing durability without adding significant weight.

5. Acoustic and Soundproofing Applications

Polyurethane foam also plays a key role in acoustic management. Open- and closed-cell foams can be converted into panels, barriers, and cushions to improve sound quality in recording studios, home theaters, offices, and public spaces. Foam conversion processes, such as CNC profiling, die-cutting, and laminating, allow customization for specific acoustic needs.

Foam Conversion and Customization

One of the most significant advantages of polyurethane foam is its adaptability. Foam conversion refers to processing raw foam materials into products that meet specific requirements. Techniques include:

- Cutting: Creating specific shapes and sizes using band saws, water jets, or CNC machines.

- Moulding: Forming foams into complex shapes for industrial and construction uses.

- Laminating and Fabrication: Bonding foam to other materials to enhance properties like sound absorption, thermal insulation, or structural support.

Foam conversion enables industries to tailor products for packaging, medical cushions, automotive components, and customized building panels. This adaptability ensures that polyurethane foams can solve unique challenges where standard materials fall short.

Environmental Benefits of Polyurethane Foam

Sustainability is a key consideration in modern construction and industrial design. Phenolic and polyurethane foams have a low environmental impact per unit of thermal performance. Many foams are available in CFC-free and HCFC-free forms, contributing to reduced greenhouse gas emissions. By improving energy efficiency in buildings and vehicles, polyurethane foam insulation supports national and international CO₂ reduction targets.

Advantages of Polyurethane Foam Insulation

To summarize, the main benefits of polyurethane foam insulation include:

- Superior thermal insulation and energy efficiency

- Lightweight yet strong structural support

- High chemical, moisture, and fire resistance

- Versatility across commercial, industrial, and residential applications

- Acoustic and vibration control capabilities

- Customization through advanced foam conversion techniques

- Environmentally friendly options with minimal carbon footprint

These advantages make polyurethane foam a material of choice for engineers, architects, and industrial designers who require high-performance solutions for challenging environments.

Conclusion

Rigid polyurethane foam and polyurethane foam insulation are at the forefront of modern material technology. Their unique combination of thermal efficiency, structural strength, fire resistance, and acoustic properties makes them indispensable across a wide range of applications. From construction and refrigeration to automotive, aerospace, and soundproofing, these foams provide innovative, cost-effective, and sustainable solutions.

As industries continue to demand lighter, stronger, and more environmentally conscious materials, polyurethane foams remain a reliable choice for manufacturers and designers alike. By selecting high-quality polyurethane insulation and leveraging advanced foam conversion techniques, businesses can achieve superior performance while meeting safety, regulatory, and sustainability goals.